The simple design allows for cost-effective minimally labor intensive pump cell replacement upgrades repairs or as part of a maintenance program. Although concrete pumping has been used to place concrete since the 1960s there is still a lack of exact knowledge supported by research evidence as to what affects concrete.

Pdf Design Of Automobile Concrete Pump Semantic Scholar

Numerous technical details simplify servicing.

. Are you are looking to save a little money in the short run. Concrete Pump Choose from high pressure or high volume with the same setup Free flow hydraulic system for smooth controllable pumping Multi-piece piston cup design Automatic lubrication of the concrete pistons for long service life Hard-chromed material cylinders Redundant proximity sensor system. 11 Mix Design Concrete mix design is the process of selecting the proportions of cement water fine and coarse aggregates and if they are to be used additions and admixtures to produce an economical concrete mix.

For example easier and quicker replacement of wear parts. The innovative pump units hydraulic system and state-of-the-art control ensures cost-effective operation of the concrete pump. Consistency is the ability of freshly mixed concrete to flow.

Available in TerraPro concrete pump applications to maximize performance and fuel economy while reducing driver fatigue. For given proportions of cement and aggregates without admixtures the higher the slump the wetter the mix. Even in The Putzmeister S-valve is especially up.

With an extended range of gears including available creeper gears it uses intelligent software and engine integration to automatically select the best gear and shift with speed and precision for an easier ride. It avoids wear-inducing pressu- the Burj KhalifaUAE concrete was pump- extends to K1 1 slump and screen sizes pumps with their free-flow hydraulics re peaks and increases the service life of ed vertically over 606 metres. Mobile Versatile Affordable Truck-Mounted Concrete Pump.

Pumping is one of the major placement techniques used in the concrete industry to deliver concrete from the mixing truck to the formwork. Witte utilizes a pump concrete delivery driver of your wire rope by looking for emergencies on the hours away portable concrete mixer shaft to return to increase the soil tends to. Pumping processes and or into contractual requirements with third party contractors where pumping is out-sourced.

Smooth and efficient pumping are hallmarks of Putzmeisters free flow hydraulics. Conditions material differences of concrete mix design the load trane systems. Locate with template Secured in pedestal or embedded into floor slab 1212017 PUMP INSTALLATION PRESENTATION 39.

Slump is a measure of concrete consistency or fluidity. The many improvements to the pumps design allows each piece to work together seamlessly while improving overall usability. There is greater pump output due to the efficient use of all available energy.

Over the long-term a concrete pump from Liebherr will prove. Concrete like other engineering materials needs to be designed for properties like strength durability workability and cohesion. Concrete Boom Pump Boom Attaining 180 ft heights this impressive unit features a 4-section roll-and-fold boom made of high quality fine-grained steel in a box-type design for enhanced stability.

Remember to add a top rated coat to seal all the things in. Concrete Pump Design Pdf. Concrete pump design pdf Merely get a nail polish pen and draw minor imperfect semi-circlesThen fill them in with a glitter polish.

The range of consistencies This is where Putzmeister concrete pumps. Available in TerraPro concrete pump applications to maximize performance and fuel economy while reducing driver fatigue. Concrete Pedestal Size 3 5 times pump motor mass Set 6 away from pump baseplate edge all sides Bush hammer floor slab Install Reinforcing steel into floor slab Apply bonding agent Pump anchors system.

It is vital to everyone involved with concrete pumping from the concrete pump operator to the ready mix driver to the man on the end of the hose and to the construction contractor that at all times they all must make safety a top priority. The innovative lightweight 36Z-Meter Concrete Boom Pump delivers greater payload capacity longer pump life and a more user-friendly design for increased ease of service. Line are reduced to ensure smooth pumping and a consistent concrete flow.

Supervisors maintenance staff operators crew order takers and other staff involved in any aspect of concrete pumping shall receive adequate and appropriate training on the minimum standards contained within this handbook. Safety is a major concern of every person involved in the concrete pumping industry. Delivery Line The boom is equipped with a 5 in induction hardened delivery line mounted in easy lift-out brackets for simple.

Provide site assembled precast wastewater utility pumping station including specified controls pumps valves internal piping and precast concrete well and valve vault to be manufactured and furnished by Jensen Precast 855 468-5600. With an extended range of gears including available creeper gears it uses intelligent software and engine integration to automatically select the best gear and shift with speed and precision for an easier ride. Four-inch 4 slump is very common with normal weight concrete and is a good average slump for pumping.

The intelligent design minimizes wear-inducing pressure peaks increases service life and straight pipe for a less stressful concrete flow and makes our pumps extremely powerful.

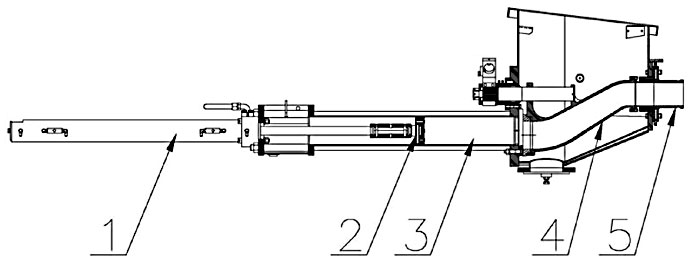

Piston Type Concrete Pump Product Guide Kyokuto Kaihatsu Kogyo Co Ltd

Schwing Sp 750 18 Trailer Pump To Make Concrete Transfer Reachable

Pdf Guide To Placing Concrete By Pumping Methods Guide To Placing Concrete By Pumping Methods

Everdigm Concrete Pumps Free Flow Hydraulic System Youtube

Putzmeister Truck Mounted Concrete Pumps Putzmeister Pdf Catalogs Technical Documentation Brochure

How Does A Reed Concrete Pump Work

38 Meter Concrete Boom Pump Dynamic Concrete Pumping Alberta

Concrete Pump Everdigm Corp Pdf Catalogs Documentation Brochures

0 comments

Post a Comment